Streamline your operations with expert-engineered labels

Tired of off-the-shelf labels that cause more problems than they solve? CleanMark custom engineers our labels to meet your most complex needs and then delivers them quickly and reliably, so you never have to think about a label again.

Upgrade to custom labels

- Give us some initial information

- Talk to a label expert

- Review and test your custom label

- Production and shipping

True customization engineered by experts

When we say our labels are custom engineered, we don’t mean that we give you a few options to choose from on an order form. We mean that we partner with you to design and produce a label that meets the unique demands of your environment and processes — even if that means imagining a completely new kind of label.

Designed

by engineers with industry-specific experience

Optimized

for the exact needs of your use case

Supported

long-term by our team of experts

The best labels are invisible

We worry about labels so you can worry about innovating. We partner with you to design and produce a label that meets the unique demands of your environment and processes — even if that means imagining a completely new kind of label.

- Eliminate delays and stress

CleanMark labels perform reliably day in and day out. - Stay nimble with fast turn times

CleanMark’s turn times are the fastest in the industry. - Increase efficiency and reduce waste

CleanMark labels maximize ROI with smart design and material choice.

Explore our full range of label, tag, and tape solutions

It’s not simple to create a label that meets the complex requirements of your unique environment and processes. Our broad spectrum of product features gives us the flexibility we need to create the ideal solution for you.

Cleanroom labels

No particulate contamination or outgassing

Cleanroom tape

Useful for sealing packaging and protective garments and marking floors

Cleanroom tags

Flexible, contamination-free identification

Sterile labels

Irradiated to eliminate microbial contamination

Autoclave indicator labels

Easy-to-read results based on steam, temperature, and time

ETO indicator labels

Color change under pressure, exposure, temperature and duration consistent with sterilization

Gamma indicator labels

Color change under irradiation dose process consistent with sterilization

Chemical resistant labels

Resistant to degradation caused by harsh chemicals

Heat resistant labels

Maintain integrity and legibility at high temperatures

Freezer labels

Designed for temperatures between 0°C and -40°C

Cryogenic labels

Ideal for liquid nitrogen environments of -196°C

Refrigerator labels

Cold chain labels designed for use between 2°C to 8°C

Dry ice labels

Optimized for ultra-low temp lab freezers between -40 °C and -80 °C

Waterproof labels

Maintain integrity and legibility in high-moisture environments

Direct thermal labels

Optimized for use with direct thermal printers like Zebra and DYMO

Thermal transfer labels

Perfect for Zebra, DYMO and other thermal transfer printers

Laser labels

Ideal for detailed text and graphics printed on major laser printers

Inkjet labels

Optimized for vibrant colors printed on major inkjet printers

Our business is to know your business

Whether you’re a semiconductor manufacturing engineer or a pharmaceutical supply chain manager, we’ll assign a team to you who is experienced in your field and knows how to solve your most common (and most complicated) challenges.

We’re a strategic partner

Looking for more detailed information?

Explore case studies, articles, guides and more in our extensive library of labeling resources.

Achieve cleanroom manufacturing traceability with custom tags

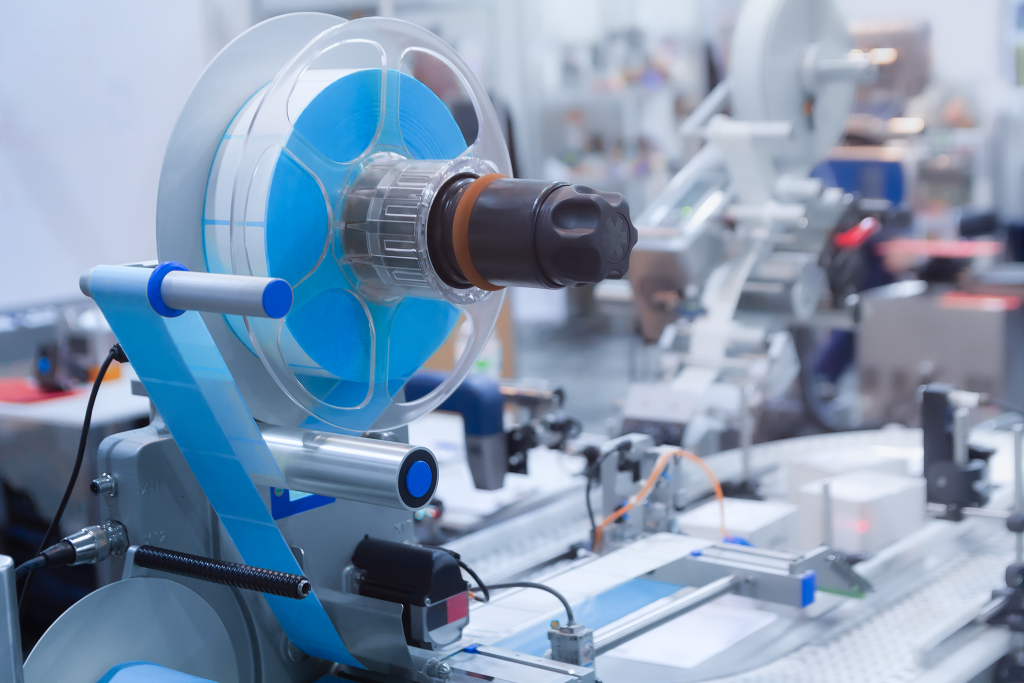

Which label is right for your label applicator machine?

Are you labels contaminating your aseptic environment?

Stay up to date on labeling advances in your industry

From white papers to industry surveys and ebooks, we’ll make sure you’re informed about the latest technology that can make your operations more efficient and less stressful.

Have more questions? We have answers!

Read on for answers to our customers’ most common questions.